Core Benefits of Herbal Soap

Herbal soaps are special because they clean the skin gently and do not cause itching or burning. They contain natural ingredients, such as herbs and plants, that help keep the skin healthy. These soaps come in many pleasant scents, including flowers, herbs, and earth.

Herbal soaps are celebrated for:

-

Gentle, non-irritating cleansing

-

Natural antioxidants and active botanicals

-

Variety of herbal, floral, and earthy scents

-

Suitability for all skin types, including sensitive skin

Ingredient Selection

Base Oils

The oils you choose decide how the soap will feel and work. Some soaps become hard, some make more bubbles, and some keep the skin soft.

-

Coconut oil helps the soap clean well and make foam (bubbles).

-

Olive oil makes the soap gentle and keeps skin soft.

-

Palm oil makes the soap strong and long-lasting.

When we mix these oils in the right amount, the soap becomes good in all ways hard, bubbly, and soft for the skin.

Herbs and Plants

Some herbs are often used in soaps because they are good for the skin:

-

Neem keeps away germs.

-

Aloe vera cools and heals the skin.

-

Tulsi fights fungus.

-

Chamomile makes skin feel calm.

-

Turmeric helps skin look bright.

These herbs can be mixed in oils, added as powder, or used as liquid extracts. Each herb gives its own special benefit to the skin.

Essential Oils

Essential oils give the soap nice smells and also help the skin. Some common ones are:

-

Lavender (relaxing smell),

-

Rosemary (fresh smell),

-

Peppermint (cool feeling),

-

Tea tree (keeps skin clean),

-

Lemongrass (lemon-like fresh smell).

They are chosen for both their good fragrance and skin benefits.

Lye (Sodium Hydroxide)

Lye is an important ingredient used to change oils into soap. This process is called saponification. Lye must be measured very carefully to stay safe. Don’t worry when the soap is made properly, no lye is left in the final bar of soap.

Required Equipment and Safety

Safe soap making means careful preparation and proper tools:

-

Digital scale (for accurate weighing of oils and lye)

-

Thermometer (to check temperatures during mixing)

-

Non-reactive bowls (stainless steel or glass)

-

Stick blender (for blending oils and lye thoroughly)

-

Soap molds (silicone molds are popular)

-

Gloves, goggles, apron for personal safety

Proper ventilation, child/pet safety, and a first-aid kit are also recommended.

Our Herbal Soap Manufacturing Process (Easy Steps)

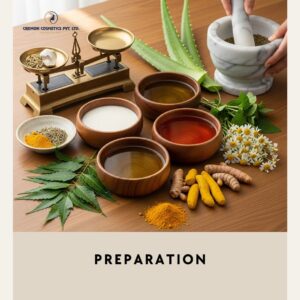

1. Preparation

First, measure all the ingredients carefully.

Soak herbs in oil or water and then strain them (this is called infusion).

If using dry herbs, grind them into fine powder to give color or a scrub effect.

2. Mixing the Lye Solution

Add lye slowly into water (never add water into lye—it’s unsafe).

Stir gently until mixed.

Let this cool down until it is warm, not hot (about 100–110°F).

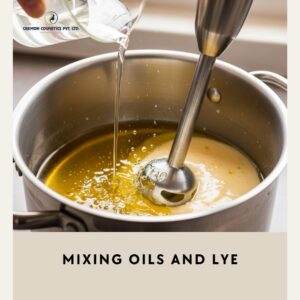

3. Mixing Oils and Lye

Warm the oils until they are the same temperature as the lye solution.

Pour the lye solution into the oils.

Use a blender to mix until it gets thicker, like pudding. This stage is called trace.

4. Adding Herbs and Essential Oils

Now add the herb infusions, herb powder, and essential oils.

Mix well so everything spreads evenly.

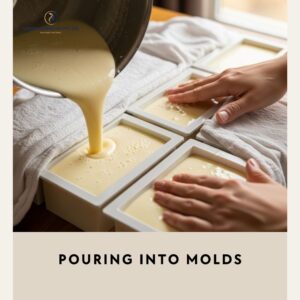

5. Pouring into Molds

Pour the soap mix into molds (shapes).

Tap gently to remove bubbles.

Cover and let it rest for 1–2 days so it becomes hard.

6. Curing (Drying Time)

Take the soap out of the molds.

Place the bars on a rack in a cool, dry place.

Leave them for 4–6 weeks, turning sometimes, so they dry fully and become gentle and long-lasting.

7. Testing and Packing

Check the soap with pH strips (safe level is 8–10).

Do a small skin test to make sure it doesn’t cause problems.

Wrap the soap in safe, moisture-free paper and label it with the name and ingredients. Eco-friendly wrapping is even better!

Industry Techniques We Use

Melt and Pour

This way uses a ready-made soap base. You just melt it, add colors, herbs, or smells, and then pour it into molds. It is quick, safe, and good for beginners because you don’t have to handle lye. The soap is ready to use as soon as it cools and becomes hard. But you cannot change everything—you have less freedom.

Cold Process

In this way, you make the soap from scratch using oils and lye. You can fully control what goes inside and add many kinds of herbs. But the soap needs many weeks to dry and become ready. This method is better for people who already know how to make soap and want more creative freedom.

Why Choose Our Herbal Soap Manufacturing?

-

We source only premium raw materials.

-

Our clean, state-of-the-art facilities follow strict hygiene and quality protocols.

-

We test consistently for safety, stability, and customer satisfaction.

-

Custom packaging and private labeling services support brand building.

-

Competitive pricing ensures affordable bulk orders without compromising quality.

Partner with Cremon Cosmetics for Bulk Herbal Soap

If you want to sell good quality natural herbal soaps for people who care about health, Cremon Cosmetics can help you. We are a trusted company in ahmedabad gujarat that makes herbal soaps in many types and in large numbers. We can also make special soaps as per your need, and the prices are affordable.

You can contact us to talk about what you want, ask for a price, and start working with us. With our many years of experience in skin care, we promise to give you safe and reliable herbal soaps.

Frequently Asked Questions (FAQ)

Q1: Why do you use lye in soap making?

Lye is necessary to turn oils into soap. This process is called saponification. Don’t worry; when soap is made correctly, no lye remains in the finished product.

Q2: What herbal ingredients do you use?

We use natural herbs like neem, aloe vera, turmeric, tulsi, chamomile, and calendula. These herbs are included in the soap in a way that maximizes their benefits for the skin.

Q3: How long does your soap take to get ready?

Soaps made by the cold process need 4 to 6 weeks to dry and become gentle and durable. We inform our customers about this waiting period.

Q4: Do you make soaps with my own brand name?

Yes, we can provide soaps with your own label and packaging to match your brand.

Q5: Can I buy in large amounts at good prices?

For premium, affordable herbal soap manufacturing in Ahmedabad, trust Cremon Cosmetics. Let’s build your brand with natural, effective soaps that customers love.

Visit Cremon Cosmetics Soap Manufacturer in Ahmedabad for more information or reach out directly to discuss your bulk order requirements.